Continuous process expandability is often a challenge for larger industrial processes and manufacturing operations. At Applied Industrial Controls, Inc., we can provide economical entry-level Industrial Internet of Things (IIoT) solutions that are scalable to match large manufacturing operations and equipment manufacturers. We can assist you with developing your operations, preventative maintenance, or complex IIoT Apps. Get in touch with us today to learn more.

How Can I Use IIoT Solutions To Analyze My Machine Performance?

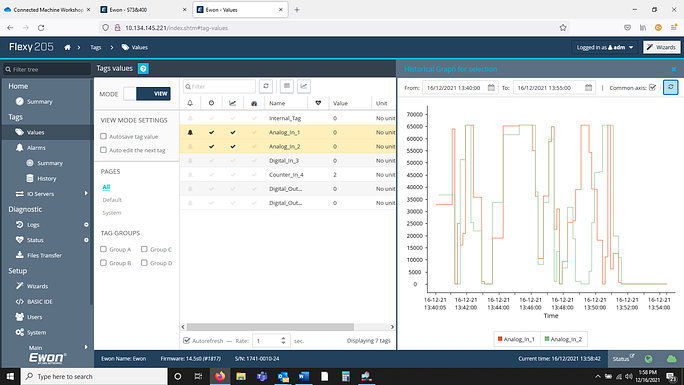

Collecting analytics or vast amounts of data from equipment in an industrial operation will help to produce valuable insights into performance efficiency. This is why IIoT exists. Analytics applications analyze machine performance and present the data in trend graphs and historical charts. Dashboard pages or displays are used to provide charts, graphs, and alarm warnings to monitor the real-time performance of equipment. As long as relevant data is transmitted from the application creating quality data sets, analytics can be used to identify cause and effect relationships and improve operational performance. Most machine designers will begin projects with a simple dashboard as the goal to obtain data on the operational efficiency of the system equipment, but an analytics application will automate performance monitoring and improvement. Statistically, less than 1% of unstructured data is used if a designer is trying to use both dashboard and analytics applications simultaneously. Trying to collect as much data as possible as quickly as possible can result in a lack of organized data and hinder the ability to achieve the desired results. This can lead to excessive operational scaling costs due to the complexity and time required to develop proof of concepts and project scope changes.How Can I Utilize My Machine Data?

Data obtained from machinery in a system is critical for condition monitoring, process efficiency, and troubleshooting. The data has a variety of applications, including:

- Developing preventative maintenance schedules

- Improving the overall performance of equipment

- Reducing operational downtime

- Increasing production efficiency

- Decreasing energy usage

- Predicting failures before they happen

- Checking for fault or alarm conditions

- Automating personnel communications

- Detecting trends throughout the system

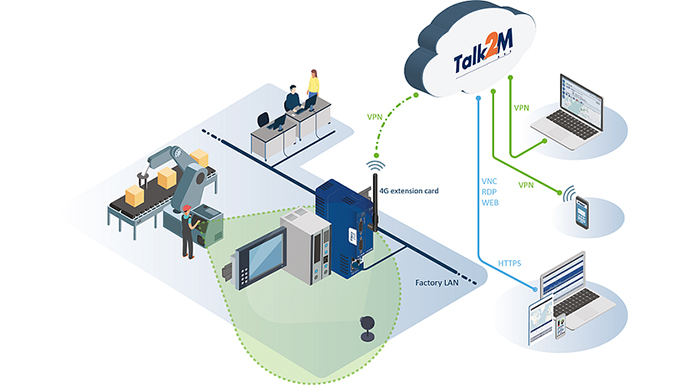

When operational data is live, it gives a real-time picture of machinery health and performance. This enables remote troubleshooting and improved support. The ability to add additional equipment, upgrade data collection, analyze equipment of an existing system, and increase the data availability for customers is a market differentiator. Smart equipment often does what the competition cannot.

What Do IIoT Opportunities Look Like?

Key Performance Indicators, or KPIs, specify values used to measure overall performance and monitor system success. With the introduction of IIoT solutions, a company will enter a higher level of digitization, enabling more advanced insights into machines and performance that were not available before. Analyzing metrics from real-time production data allows for improved process monitoring and adjustments, preventative maintenance planning, and effective troubleshooting to make timely decisions that maximize productivity.

Having machinery and process data centrally located on an interactive dashboard, IIoT allows for easy configuration of desired KPIs. These can be easily visualized with indicators, notifications, and even alarms.

What Does a Customer Facing IIoT Experience Look Like?

Customers who use IIoT within their industry need a simple user interface that meets all of their monitoring needs. They may want to monitor specific metrics of a piece of machinery or a portion of a process in a large-scale plant. They may need specific reports run and provided on a regular schedule. Whatever the need is, Applied Industrial Controls, Inc. builds custom programs and remote applications to fit any industrial process.

The most desirable features of IIoT solutions are fully customizable. These include:

- Machine control panels

- Data dashboards

- Automated schematics and graphics

- Notifications and alerts (delivered through SMS, email, and applications)

- Long term, cloud-based data storage

- Automated reporting and analytics

- Interactive graphs and trend analysis charts

- Interactive facility mapping with locations and statuses

- Preventive and predictive maintenance data

- Technical documentation

- Photo and video support content

- Machine specific parts and services information

- QR code-based permanent links

- Support requests with photo and video capture

Can You Help Me Develop an IIoT App for My Machine?

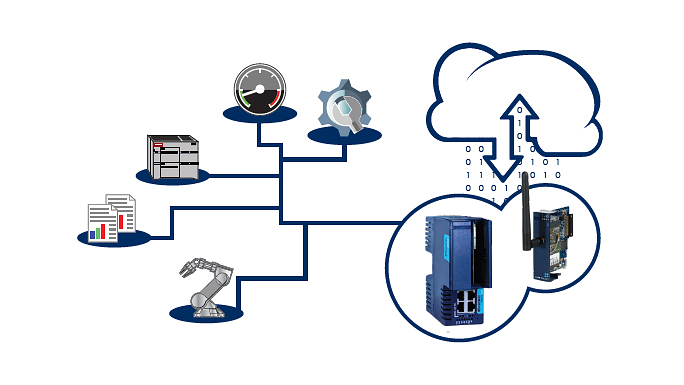

Applied Industrial Controls, Inc. can assist with developing IIoT technologies that will fully automate and improve the services available to your customers. This automation increases overall productivity, performance, accountability, and profits in industrial operations. Some of these technologies include:

- Asset tracking and visibility

- Visible data from service equipment

- Visible data from sensors and devices

- Mobile data collection for field service personnel

- Automated reporting

- Photo and video capture

- User-friendly portals

The specialists at AIC can help navigate you through the IIoT world from start to finish, including hardware and software. If you’re an engineer or maintenance professional who wants to learn these job-changing skills, we are hosting a free, interactive workshop. Click the button below to sign up!

MANUFACTURERS CERTIFICATIONS