If you're not sure whether you should be using relays or a PLC for your control panel, Applied Industrial Controls, Inc. can help. A PLC, though it appears to be complex and confusing, can take the place of multiple electrical relays and timers with many additional benefits. We can support programming requirements and educate you and your team on PLC operation and maintenance. Get in touch with us today to find out how we can help.

Should I Use Relays vs.

PLC-Based Control Panels?

What Should I Consider When

Selecting a Relay?

Should I Choose Solid State

Relays vs. Mechanical Relays?

What Is a

Monitoring Relay?

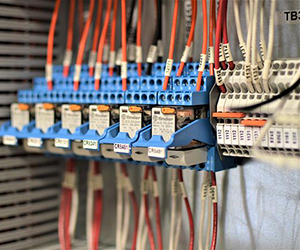

Should I Use Relays vs. PLC-Based Control Panels?

A relay is an electromechanical device that uses a coil and a contact to control an operation. The contact will switch a circuit on or off, and the function of the coil is to alter the state of the contact. Relays can be wired together in a network of circuits to perform logical operations, and this is known as relay logic. When using a PLC, logical operations are generated using ladder logic, and ladder logic was developed from relay logic. Ladder logic uses digital circuits within a software platform and a microprocessor where logic is programmed into the software. Software such as Siemens TIA Portal is a powerful tool that gives you access to a variety of digitalized automation services, from digital planning to integrated engineering and transparent operation. There are many advantages of ladder logic or PLC software over relay logic, including:- Ease of creating complex logical expressions

- Straightforward expandability to keep up with operational demands

- Increased reliability due to a lifespan of more than ten years

- Lower costs for design, installation, and replacement parts

- Optimal monitoring and reporting capabilities that enable process optimization and troubleshooting to be quicker and simpler

- Smaller size requirements than what is needed for relay logic circuitry

- Greatly reduced wiring labor

- Faster operation execution times

- Ease of adding features such as IIoT, remote access, and control

- Ease of integration with other devices such as VFDs

What Should I Consider When Selecting a Relay?

When your relays are chosen correctly, the design, operation, and reliability of your control system will be simplified. There are many factors to consider when selecting a relay to meet your needs. Some important factors to consider:

- Voltage driving the load

- Required current for the specific load

- Type of load (resistive loads, lamp loads, motor loads, capacitive loads, and inductive loads all exhibit different surges and characteristics)

- Coil Voltage

- Physical size

- Form factor/style (Form A,B,C,D,X,Y,Z)

- Number of poles

- Normally Open (NO) vs. Normally Closed (NC) contacts

- Function (timing, cycles, delay on, delay off, etc.)

Should I Choose Solid State Relays vs. Mechanical Relays?

Both solid-state and mechanical relays are switching devices in that they switch a circuit on or off based on an input signal.

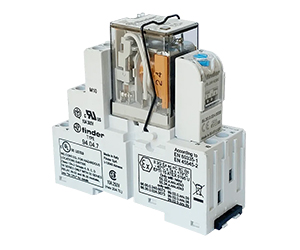

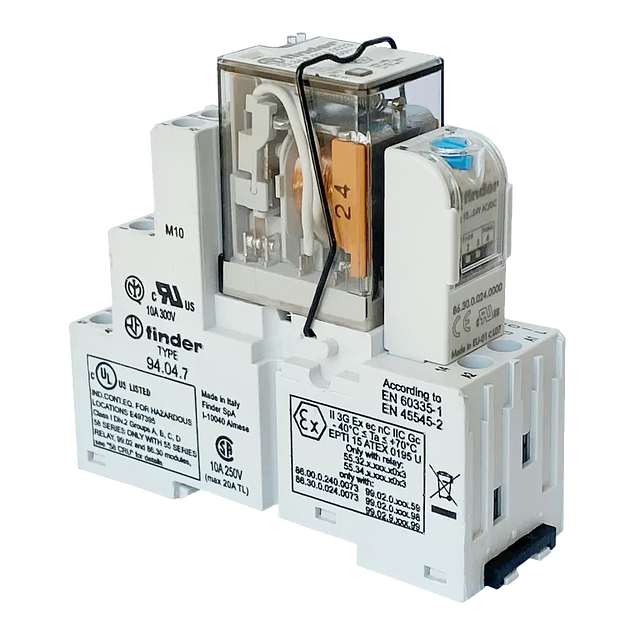

A mechanical relay is a switching device that uses a moving contact. The contact changes state or position when the coil is energized or de-energized by the input or control signal.

A solid-state relay refers to a specific type of switching device that doesn't have any movable contact. In operation, it's not very different from a mechanical relay. However, it uses semiconductor switching elements like diodes, transistors, and thyristors, which are typically used for lower current loads and higher switching life.

The primary difference between a solid-state relay and the mechanical relay is the contact movement. Due to this construction, there are also differences in dimensions, lifespan, electrical noise, speed and frequency of response time, shock and vibration tolerances, power consumption, electromagnetic interference, heat dissipation, contact wear, and other conditions that need to be considered when selecting relays for an automated controls system.

When you get in touch with one of our subject matter experts, we can thoroughly explain the differences and details so we can logically and confidently select the best relay for your operations.

What Is a Monitoring Relay?

A monitoring relay is a special type of electrical relay which acts as a protective control device designed to receive input signals, monitor those signals, identify what the signal means, and output an alarm signal if a certain value or limit is reached. Typically, a monitoring relay alarm signal is in the form of a normally open or normally closed contact. Monitoring relays scan voltage, current, temperature, power, or other analog signals to identify issues with equipment. They do this by comparing a real-time value against a user-determined alarm threshold.

We can help you specify a relay, convert your relay-based system to PLC, train your people, and reduce your costs and panel size to help take your business to an entirely new level. Get in touch with us today to get started.

MANUFACTURERS CERTIFICATIONS