Workplace safety is extremely important and is driven by OSHA codes and standards. A safe work environment reduces the risk of injury and asset damage, workers' compensation claims, and liabilities. AIC can help ensure your operations or products meet and even exceed safety requirements. Contact us with any questions and ensure your machines are fully protected and up to code.

Should I Choose a Safety Relay vs. Safety PLC?

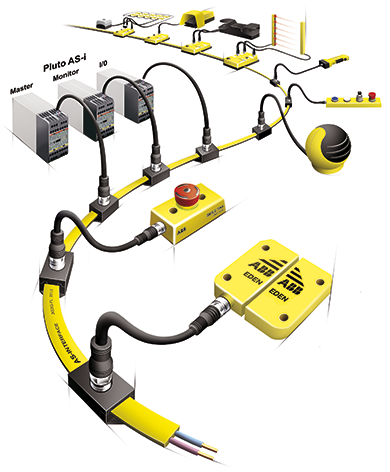

When choosing between a safety relay or safety PLC for your safety control circuit, it is necessary to know the capabilities of each, as well as the requirements of the application. Sometimes, one system will not fit an application, and a hybrid safety system will often be the best option. Safety Relay Based System – Use safety relays in medium to high-risk operations with simple and stable applications. The cost of equipment and installation keeps the expense of this system fairly low. There are a variety of these systems available. The simplest involves a control device (the safety relay) and the actuation device, such as a light curtain or emergency stop button. More complex systems can involve controlling and monitoring specific devices and multiple terminals to monitor two or three safety devices. Safety PLC Based System – Use safety PLCs in high-risk operations or where the application is complex or will change over time. The cost of equipment, installation, programming, and training makes this system more expensive than a safety relay-based system. Safety PLC systems have more capabilities than a safety relay system. They provide flexibility within the programming that allows easy expandability, and system modifications are fast and simple. Programming can be done offline, taking the place of time-consuming rewiring, which can shut down an assembly line. They have multiple I/O ports (input and output), can transmit data to other devices, offer zone control for larger operations, and ease troubleshooting to reduce downtime.Should I Use a Safety Relay vs. Standard Relay?

When it comes to safety relays and standard relays, it's important to note that a standard relay is only used for linking contacts and switching in control circuits. A safety relay has additional monitoring functions and features that are used to control a combination of devices. Standard relays are used in almost every automation function, and safety relays are specifically used in automation safety applications. For example, if the contacts of a standard relay are welded together, the equipment will run until de-energized by human intervention. With a safety relay, the equipment will immediately stop. Safety relays also utilize multiple channels using redundant signals to ensure operations start and stop correctly.

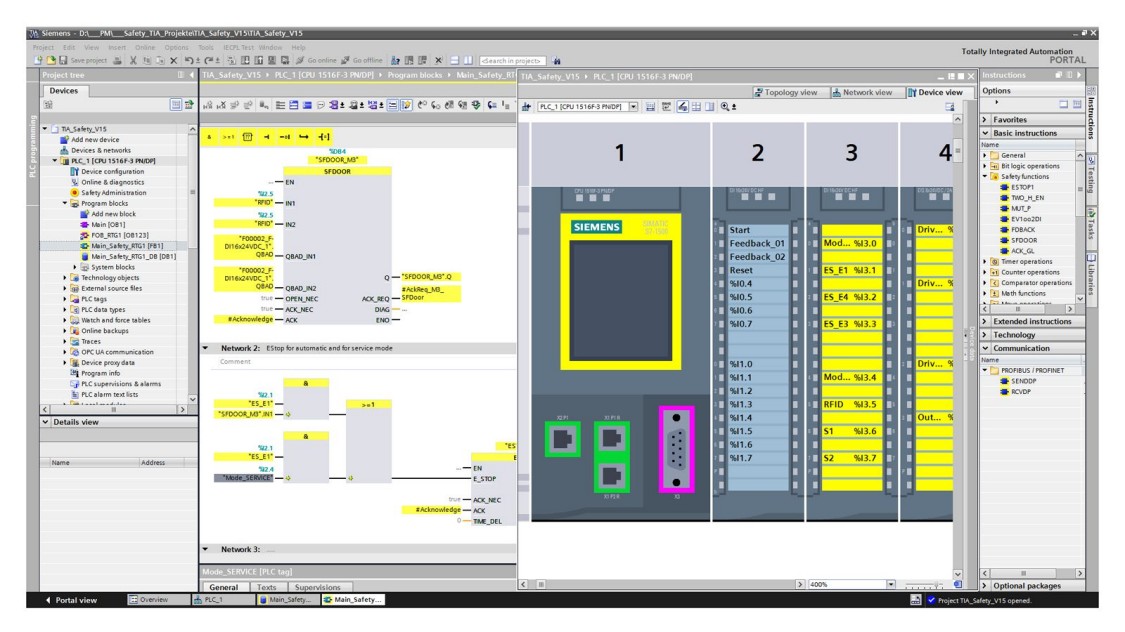

With the Siemens S7-1200, S7-1500, and ET-200 safety PLC lines, safety and standard inputs and outputs can be mixed throughout the PLC. This can lower the cost of the entire safety circuit while introducing added system flexibility. Best of all, the safety PLC can still be programmed from the same Step 7 TIA portal software.

What Other Machine Safety Devices Might I Need?

There are many areas where hazards are present in an industrial process or operation. It is important to identify these areas and implement hazard controls to limit the risk to personnel and equipment. Some safety devices available for hazard control are:- Emergency start and stop control devices

- Safety interlocking switches

- Safety light curtains

- Safety scanners

- Indicating lights

- Tower lights or stack lights

- Safety controllers

- Enabling devices

- Floor mat switches

- Foot switches

- Two-hand control devices

MANUFACTURERS CERTIFICATIONS