Rely on AIC To Provide Complete Turnkey Solutions for Your Engineering Services

Why Is AIC

a Good Partner?

Does AIC

Program?

What Is

EPLAN?

Why Do We

Use EPLAN?

How Do We

Integrate It?

What Is the AIC Process for Building Custom Control Panels?

Applied Industrial Controls, Inc. has more than 200 years of combined experience and proven methodology. Our extensive experience allows us to be the best in successfully integrating control panels into other systems. From the start, we will take the steps necessary to ensure your project starts on the right path and stays on track until the job is complete. Not all customers will have a project scope already defined. We can determine the project scope by following a sequence of operations (SOO). We also plan and schedule deliverables, propose the system architecture, and then use our experience and tools to ensure the project progresses successfully.

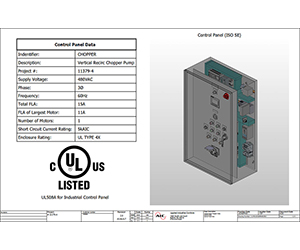

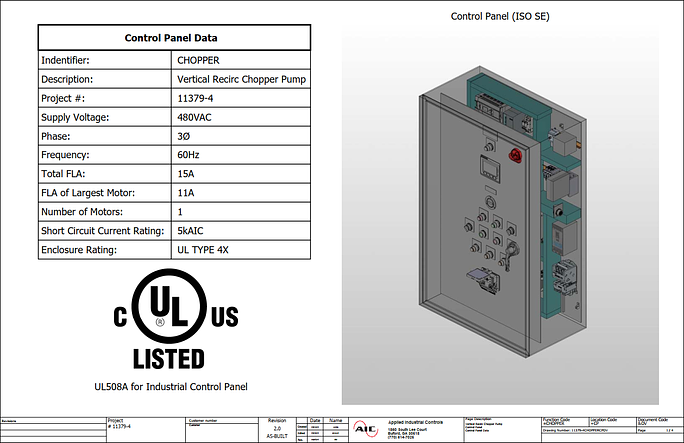

We can create detailed descriptions of your new system, commonly called Project Submittals. These are very important for municipal projects. Once this is approved, we move into the system development and control system integration stage. At this stage, we complete the hardware and software design and panel manufacturing. By conducting rigorous tests, we ensure software and machines are functioning according to the operational specifications defined by the SOO. Before any product leaves our UL508A panel shop, it undergoes internal testing and must pass a quality control inspection. Applied Industrial Controls, Inc. is one of few panel shops where team members will go on-site to commission custom control panels and train your team. On-site commissioning allows us to provide free extended warranties. Panel shops that sell their product but do not commission it do not offer extended warranties. Instead, their clients must obtain extended warranties from manufacturers. By following this process, you can feel confident that your control panel design, system integration, and programming matches your operational requirements to provide a safe, efficient, and productive system.

Why Does AIC Make a Good Project Partner?

We want to work with you, not for you. When your project needs a custom controls solution, you can count on the team at Applied Industrial Controls, Inc. to be your trusted project partner. We will design your control panel with you and your end goal in mind, making design choices during the engineering stage to help maximize efficiency during the assembly process.

AIC's team members use a collaborative approach for every project with a deep understanding through every stage of the engineering process. From design to installation and operational performance, you will have experienced and reliable engineers working on your project every step of the way. We will work closely with you and your engineers to ensure that your industrial control panel or automation system functions perfectly for its operating environment.

Can AIC Do the Programming As Well?

With customized control panel design and manufacturing, it's essential to have a program optimized for your specific application. Applied Industrial Controls, Inc. can help design and implement the solutions you need when it comes to programming, regardless of the scope of your project. For example, we can help with anything from a basic relay panel to a PLC, HMI, VFD control, and even a fully customized IIoT application. Our knowledge and experience allow us to recommend the ideal platform for your application. We strive to provide high-quality products which provide value. We can confirm this because we use the software and components ourselves daily. We excel at the following when programming your control panel:

- Understanding communication needs

- Adding new features

- Defining and following the sequence of operations (SOO)

- Designing for future expansion and development

We use programming to reduce hardware costs while selecting smarter components to help you do more with less. Finally, we'll help you properly document the code associated with the programming so that it can be modified later by our team, your internal team, or taken elsewhere.

Reach out to the team of experts at AIC to request an engineering assessment or get a quote for any engineering services or technical support you may need.

What Is EPLAN?

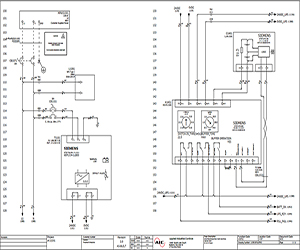

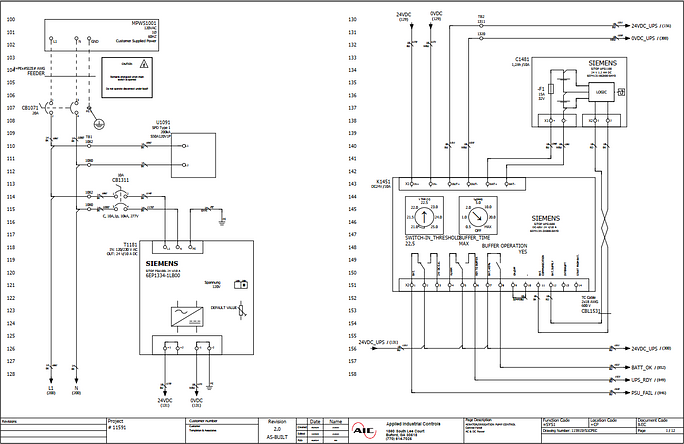

EPLAN is an electrical engineering design software that combines the functionalities of many processes in one centralized platform. The tasks and challenges faced by electrical engineers daily are no secret. Regardless of the application, hundreds or even thousands of components must be described and designed, numbered, and connected to one another in order for everything to work correctly. Schematics may need to be documented across thousands of pages, and cross-references must be created to help keep track of everything. EPLAN does all this automatically under a single piece of software.

EPLAN CAD software helps make the responsibilities of electrical engineers less challenging by offering integrated solutions. These solutions include:

- Receiving high-quality device data

- Automating engineering designs for power supplies and control systems which reduce

- Duplication issues

- Generating schematics automatically

- Generating professional and detailed manufacturing documents

- Conforming designs to international codes and standards

Why Do We Use EPLAN and How Does It Help Us Engineer Better Systems?

At Applied Industrial Controls, Inc., we use EPLAN for a variety of different reasons. It is an integrated and dependable engineering system that enables the design and planning of high-quality electrical engineering for plant systems and equipment. EPLAN software supports 2D and 3D CAD mechanical drawings, electrical schematics creation, manual drawing creation, and standardized templates. The software also generates BOMs and data document submittals, and we use it to program our Kiesling Perforex CNC Router.

When using EPLAN, our partners and clients can increase productivity, optimize and industrialize processes, reduce the time it takes to get products to market, and accurately represent the industrial control panel. EPLAN allows for quick and efficient generation of estimates, ease of schematic creation, and enhanced document quality. It also allows our engineering and production teams to collaborate, increasing production and communication efficiency. This allows us to provide quick and accurate submits to our partners in the build of approvals.

How Does EPLAN Integrate Through the Entire Custom Control Panel Engineering Process?

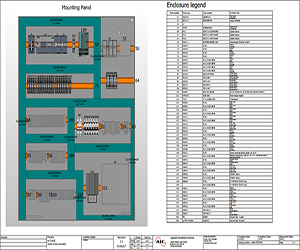

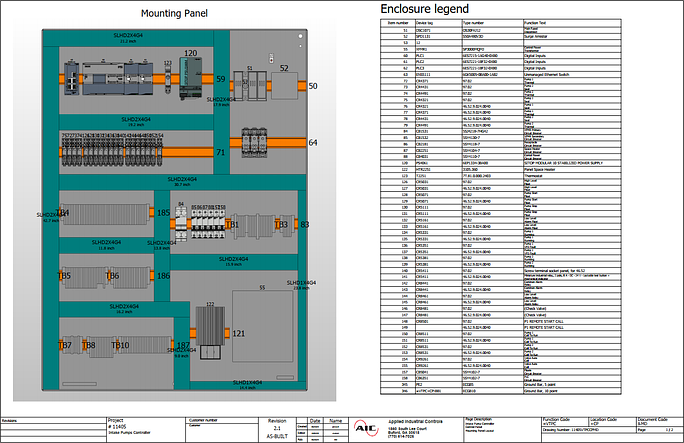

EPLAN pro panel software allows us to create a powerful and reliable foundation for automating and industrializing panel design and construction, and switchgear systems. With EPLAN pro panel, we can provide 3D design .stp files, CNC machine programming, and plan construction of control cabinets, power distribution systems, and switchgear systems.

We use EPLAN pro panel so that we can support a variety of engineering tasks using a single piece of software. Whether creating schematics and planning mounting layouts in 3D or routing electrical connections virtually, the increased options and automation allow us to complete your job more efficiently. From mass customization of a single panel to high-volume production, we can save you time and money through each step of the process and increase profitability.

MANUFACTURERS CERTIFICATIONS